what is production impact testing|examples of impact testing : ODM An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a . JOGA.pt tem a melhor coleção de jogos de Jogos de Boa Sorte, Charlie! de Portugal e do Brasil! Escolha um jogo Jogos de Boa Sorte, Charlie! ou um dos outros jogos .

{plog:ftitle_list}

webBaixar Hentai e Ler mangás, manhwas e quadrinhos adultos online. Faça amigos, organize seus favoritos, ganhe medalhas e entre para o nosso ranking. Aqui você pode ler online .

why impact testing is done

If you are working to ASME Sec VIII, you must perform a production test on material from one of the heats used in production. Only category A and B welds must be represented, so, only welding processes used for those applications must be tested.Is it required that the material I use for the procedure qualification be impact .

Is it required that the material I use for the procedure qualification be impact tested? Material used in production would be impact tested, but I am wondering if my PQR .

test shoulder labral tear

An impact test is a technique used to determine a material’s ability to resist deformation when subjected to a sudden shock or impulse load. There are several different types of impact tests, but all entail striking a .Explain the principles of production impact testing, when it is required, and the applicable conditions for performance and acceptance. Who Should Attend. This MasterClass is intended .What is required for each production run is per UHA-51(h) Vessel (Production) Impact Tests of weld coupons including base metal, weld metal, and HAZ. For austenitic chromium-nickel stainless steels paragraph UHA-51(h)(2) refers . What is Impact Testing? Impact testing is a procedure that measures a material’s resistance to failure when subjected to high-rate loading. This method is used in multiple industries like automotive, .

In automotive and other safety-critical industries, impact testing is an important measure of a material’s failure properties. Properly testing both raw materials and molded components for their strength and durability can .Impact testing is testing an object's ability to resist high-rate loading. An impact test is a test for determining the energy absorbed in fracturing a test piece at high velocity. Most of us think of it as one object striking another .

Impact testing can test a material’s ability to withstand sudden or repetitive shock loads. Testing the material’s durability against these repeated impacts is also possible. Using an impact testing machine, it is performed by impacting .An overview of mechanical and physical testing of composite materials. N. Saba, . M.T.H. Sultan, in Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites, 2019 1.2.3 Impact test. The impact test is designed to determine how a specimen of a known material such as polymers, ceramics, and composites will respond to a .

Production Testing as the Future – Many organizations are concerned about the notion of testing extending into production since testing has often certified the quality of the software before delivery to production. .An impact test is designed to replicate situations in which an object or material will react when subjected to an impact load that instantaneously causes the specimen to deform, fracture or completely break. These tests evaluate the . Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads. These characteristics are vital for selecting materials that meet specific application requirements, resulting in safer and more .production welds or as close to the start of production welding as practicable. (2) When Required. Vessel (production) impact test plates shall be made for all joints for which impact tests are required for the welding procedure byUCS-67, UHT-82,orUHA-51 (except where production test plates are specifically exempt by these paragraphs). Test shall

Software testing is the process of evaluating and verifying that a software product or application does what it’s supposed to do. . and even occurs when deployed into production. Continuous testing means that organizations don’t have to wait for all the pieces to be deployed before testing can start. . measure their scope and impact .Testing in production enables you to see how your updated product or features will work in the real world. Learn what it is, why it matters, and how to use it. . Negative user impact: If not properly controlled, you could expose your users to bugs, downtime, .

Before looking at impact testing let us first define what is meant by 'toughness' since the impact test is only one method by which this material property is measured. Toughness is, broadly, a measure of the amount of energy required to cause an item - a test piece or a bridge or a pressure vessel - to fracture and fail.

Impact testing is testing an object's ability to resist high-rate loading. An impact test is a test for determining the energy absorbed in fracturing a test piece at high velocity. Most of us think of it as one object striking another object at a relatively high speed. Why is Impact Testing Important?

Pre-use testing is accomplished by doing weld coupons and testing the weld metal. One might think this is accomplished by using the impact test data from the Vessel (Production) Impact Test coupons, however there are additional requirements and exemptions that make for a convoluted logic tree to get to the correct conclusion.Its impact has prompted a shift in mindset, encouraging businesses to reimagine processes and leverage the full potential of automation. . Furthermore, a well-configured test environment is essential for reliable automation testing. It mirrors the production environment closely by replicating the necessary hardware, software, and network . Answer: In this case, you need to make sure that the company that is performing the welding on the long seams is aware that the vessel requires production impact testing.They will be responsible for performing the production impact testing for the long seams that they are welding. They will need to supply you with all of the applicable testing reports.lification test plates and vessel test plates (production impact test plates) shall be determined as required in this paragraph. (b) All test plates shall be subjected to heat treatment, including cooling rates and aggregate time at temperature or temperatures as established by the manufacturer for use in actual manufacture.

ImPACT, which stands for Immediate Post-Concussion Assessment and Cognitive Test, is a common testing protocol in the area of brain injury. Developed in the late 1990s at the University of Pittsburgh and released in the early 2000s, the test is the only FDA-approved tool for concussion assessment. Testing in production is a software development practice that tests an application in a live environment. Read this article to learn more about it in detail. . This will minimize the impact on your users. Do loading time tests . In general, if the base metal requires impact testing, so will your WPS, and production impact test would be required. If you order material meeting UCS-66(g)it will already be impact tested, but is considered exempt. It's a fine line between material the requires impact testing vs material that is already impact tested, so is therefore exempt.

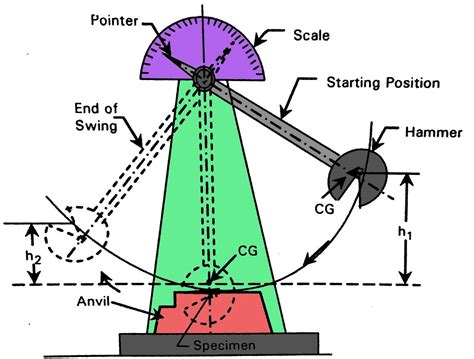

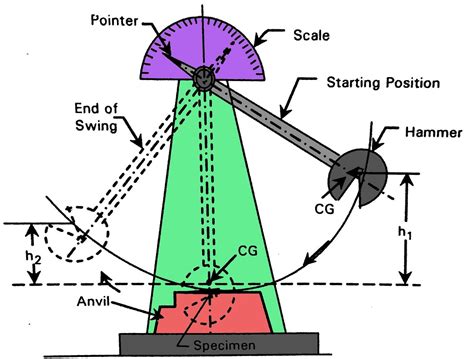

That is to say, in-production testing is meant to supplement rather than replace testing in a pre-production environment. The execution of software tests in a live environment is referred to as production testing. Because it reflects the real world, it is a good approach to software testing.IMPACT TESTING MATTERS, NOW MORE THAN EVER 1.1 What is a Pendulum Impact Test An impact test determines a material’s resistance to an impact event. It measures the amount of energy the material absorbs when it is hit by a high-rate load. The most common impact test methods are Charpy and Izod and are typically run using a pendulum impact tester.

The Charpy impact test shows that materials with higher toughness can withstand unexpected stresses and impacts in a building or machinery component. . Our professionalism can guarantee the quality of products. A professional R&D team and advanced production line make OTS the best testing machine manufacturer around you. Contact. Tell:+86 .ImPACT is a computerized concussion assessment tool for ages 12-59. By comparing baseline and post-injury ImPACT test results, you can make confident treatment decisions.

Notched bar or impact testing – Part 1 Before looking at impact testing let us first define what is meant by 'toughness' since the impact test is only one method by which this material property is measured. Toughness is, broadly, a measure of the amount of energy required to cause. Impact testing is another common kind of mechanical testing. This is for parts that take high-impact loads. For example, car bumpers. If a bumper breaks upon impact, it is a bad design that is unsuitable for cars. Therefore, in an impact test, engineers apply impact loads with a known force, time period, and number of cycles to determine impact .

Bones: Parathyroid hormone stimulates the release of small amounts of calcium from your bones into your bloodstream.; Kidneys: Parathyroid hormone enables the production of active vitamin D (calcitriol) in your kidneys.PTH also signals your kidneys to retain calcium in your body rather than flushing it out through your urine. Small intestine: Parathyroid hormone .

Testing in production is testing the application in the production environment. Discover what production testing is and the best practices. . This may impact the test results. Enhances Deployment Frequency. Frequently releasing new code or features during testing in production also improves agility. You can respond to customer requests more .Impact Testing Enigma Issued 2023-10-04 AB-511 Edition 3, Revision 1 Page 2 of 18 2.0 DEFINITIONS Enigma – Something hard to understand or explain (ster’s Ninth New Collegiate Dictionary). Fined Grain Practice – The procedure necessary to obtain a fine austenitic grain size as described in SA-20.What is Testing in Production? The goal of testing in production (TiP) is to quickly detect bugs in a production environment in order to minimize their impact on users. By making a production environment more test-friendly, testers can ultimately improve the overall quality of a product or software service.Based on the ASME impact test requirement, you need to make assessment to see that either your pressure vessel is exempted from impact testing, or you need to carry out the test. There are 4 steps for impact test exemption assessment. You need to know these steps.

test tears for csf

Resultado da 14 de nov. de 2018 · Max Win: 7,325x. Volatility: Medium/High. Min/Max Bet: 0.10/100. Release Date: Out .

what is production impact testing|examples of impact testing